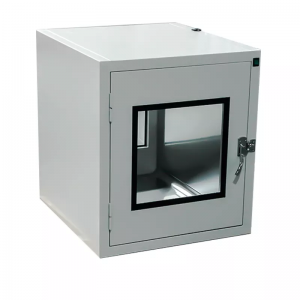

Clean room air shower pass thru box for pharmacy or lab

Product introduction

The air shower transfer window(pass box,pass thru box) is a purification device that is set on the partition wall between the clean area and the non-clean area at different levels, and is used to transfer items to each other. The clean area enters the surface purification of the high-level clean area. When transferring materials, a high-speed, clean air flow is blown out from the top to blow off the dust particles on the surface of the goods. At this time, the doors on both sides can be opened or closed, and the clean air flow acts as an air lock. In order to ensure that the air outside the clean room will not affect the cleanliness of the room, the air shower transfer window can effectively remove the dust on the surface and prevent the dust from being carried into the clean room by the material. According to the technological requirements of the product, it can be made into air shower transfer window and ordinary transfer window. The air shower transfer window can generate clean high-speed airflow to blow the article during the transfer of the article, remove the dust on the article, and make the clean room free from pollution. The clean transfer window is widely used in PCB, IC manufacturing, LCD, optoelectronic products, aseptic packaging, food processing industry, electronics factory and other places where air purification is required.

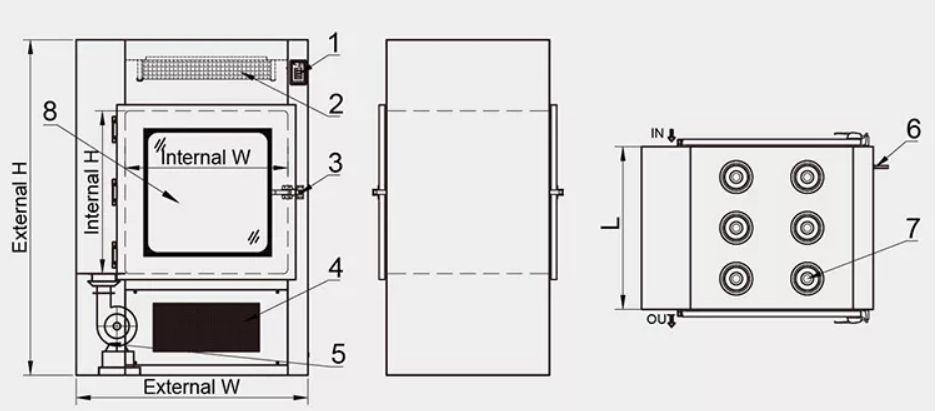

Specification

| Item | QH-600 | QH-750 | QH-800 | |

| External Size (WxLxHmm) | 940x600x1450 | 1090x750x1600 | 1140x800x1650 | |

| Internal Size (WxLxHmm) | 600x600x600 | 750x750x750 | 800x800x800 | |

| Nozzle in stainless steel (pc) | 4 | 6 | 6 | |

| Noise (1m away) (dB) | <65 | <65 | <65 | |

| Fan | Power supply (V/Hz) | 380/50 | 380/50 | 380/50 |

| Power (W/set) | 750 | 750 | 750 | |

| Quantity /set | 1 | 4 | 1 | |

| Air flow (m³/h) | 1200 | 1200 | 1200 | |

| HEPA filter | Size (W×H×Dmm) | 484×484×69 | 630×630×69 | 630×630×69 |

| Efficiency (>) | 99.99% | 99.99% | 99.99% | |

| Pre-filter size (W×H×Dmm) | 525×275×17 | 560×275×17 | 560×275×17 | |

Features

1. The full cold plate structure is commonly used, the inner wall of the stainless steel plate is smooth and clean, the appearance is beautiful, and the service life is long.

2. The two sides of the box are equipped with open-door signal indicators, which can know the opening of the opposite door.

3. The doors on both sides are equipped with mechanical interlocking or electronic interlocking and electronic latching devices to ensure that the doors on both sides cannot be opened at the same time.

4. Various non-standard sizes and floor-to-ceiling transfer windows can be customized according to customer needs.

5. Using EVA sealing material, high sealing performance.

6. Ultraviolet germicidal lamps can be added, or replaced by electronic interlocking. (price is negotiable)

Installation method

Choose a convenient location on the wall, and then open the hole. The hole is generally about 10mm larger than the outer diameter of the transmission window. Put the transmission window into the wall, generally install it in the middle of the wall, keep it balanced and fixed, and decorate it with rounded corners or other decorative strips. The gap between the transmission window and the wall can be sealed and decorated with glue.

Specific parameters:

Outer size: width 900* depth 600* height 1550, inner size: 600*600*600,

If you need to add a germicidal lamp +100 yuan, if you need to replace the electronic interlock +300 yuan

Electricity: 380/30hz/3phase or 220v/50hz. 1phase.

+86-18038493642

+86-18038493642